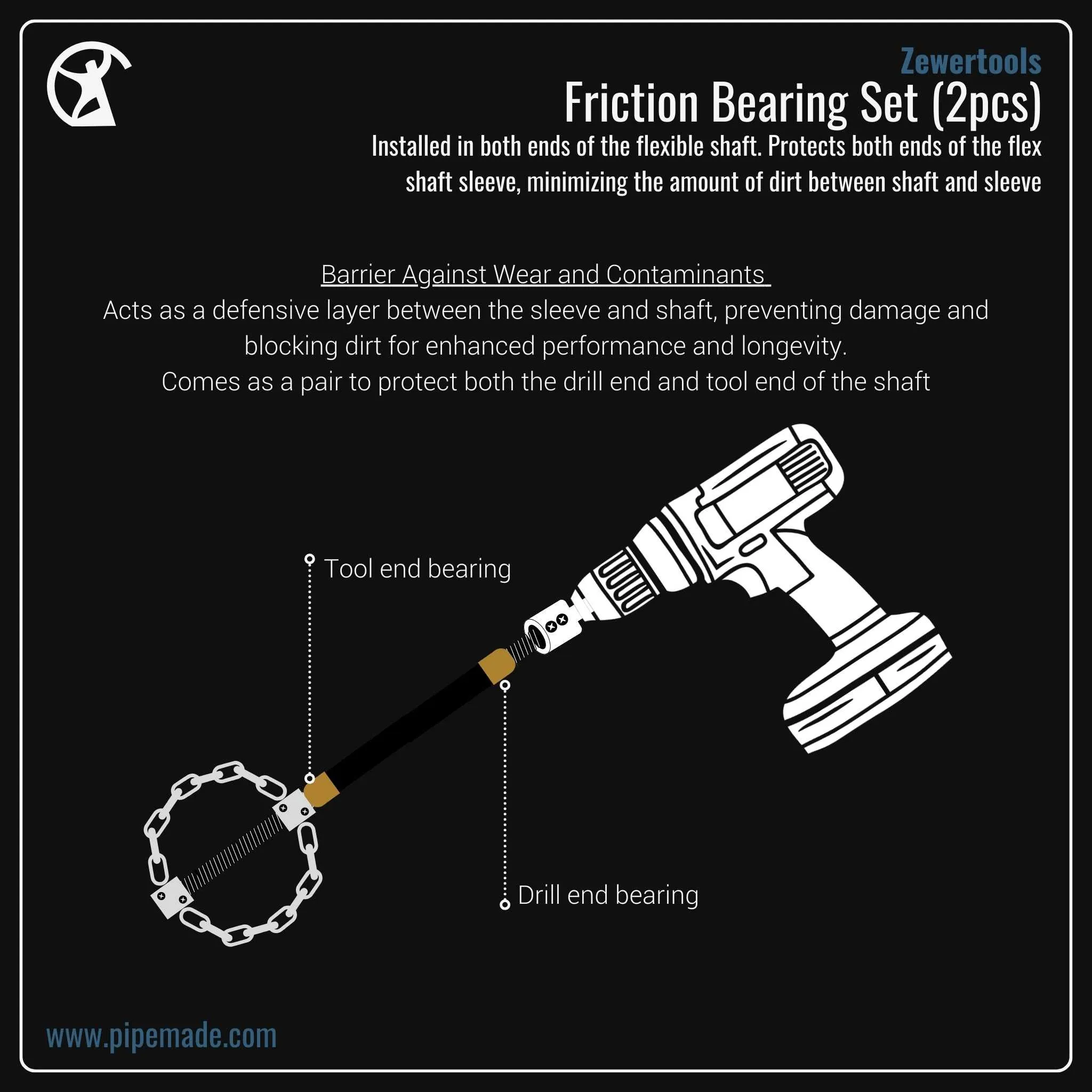

Protect the flexible shaft with friction bearings

These bearings are an absolute must when using flexible shafts. That is why they are included with all of our flexible shaft sets. So IF you're buying the Flexible Shaft Set with Friction Bearings you will most likely not be needing these.

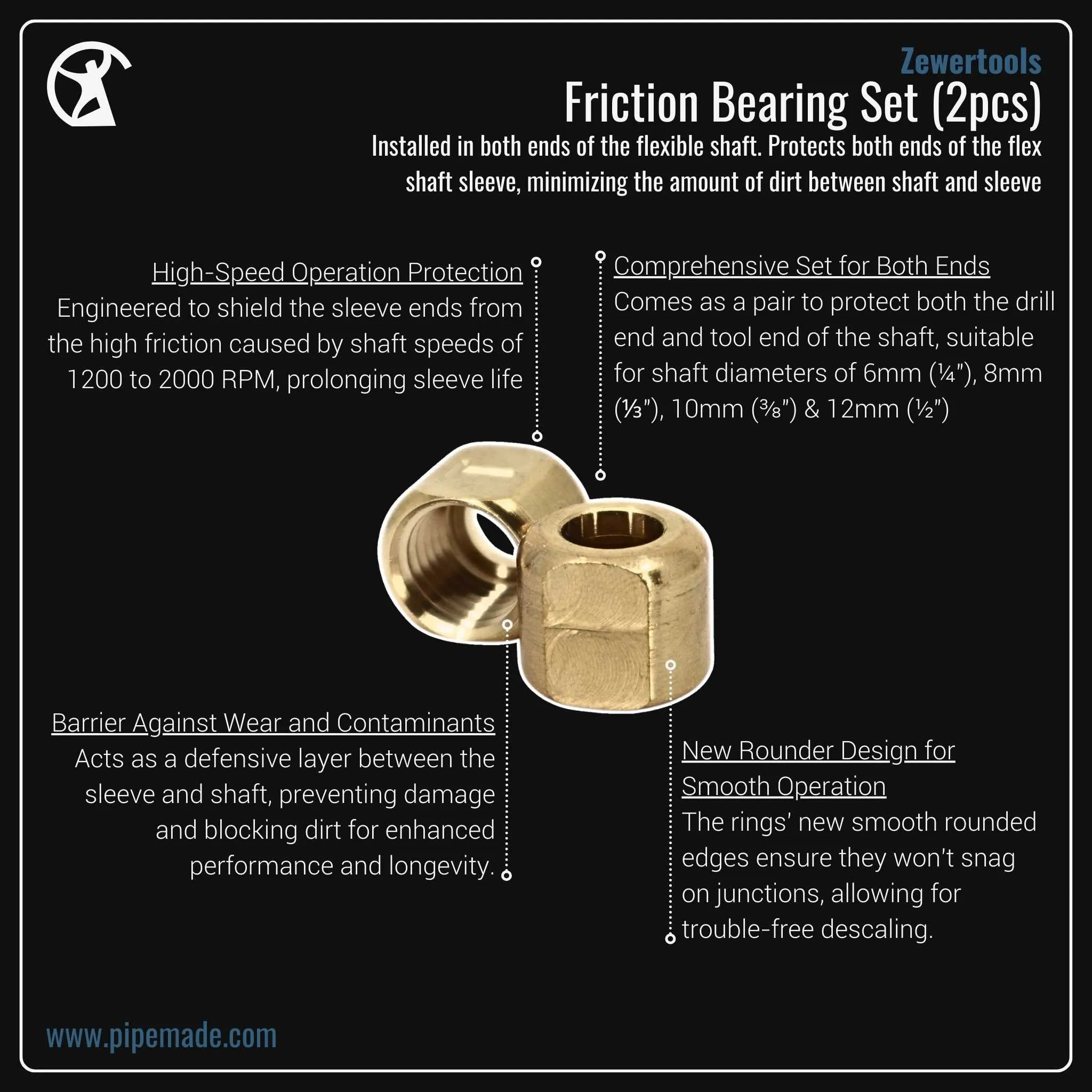

Imagine that you're descaling a pipe and the flexible shaft rotates easily about 1300 RPM and usually more. That causes a lot of friction from the flexible shaft from both ends towards the protective sleeve around it. The friction bearings are the solution for that.

The Friction Bearings are installed in both ends of the flexible shaft. While protecting both ends of the flex shaft sleeve, the bearings also minimize the amount of dirt between shaft and sleeve that might tag along during jobs. This means longer lifespan and less cleaning & maintenance to the shaft.

If you do not have a Friction Bearing in your flexible shaft and you're operating it with a cordless drill there is a possibility that the sleeve might come in contact with the Drill-to-Shaft Connector and the friction between connector and flex shaft sleeve might heat the sleeve and even melt it. This is also why you should consider adding the friction bearings if you ever have a flexible shaft without any equipped friction bearings.

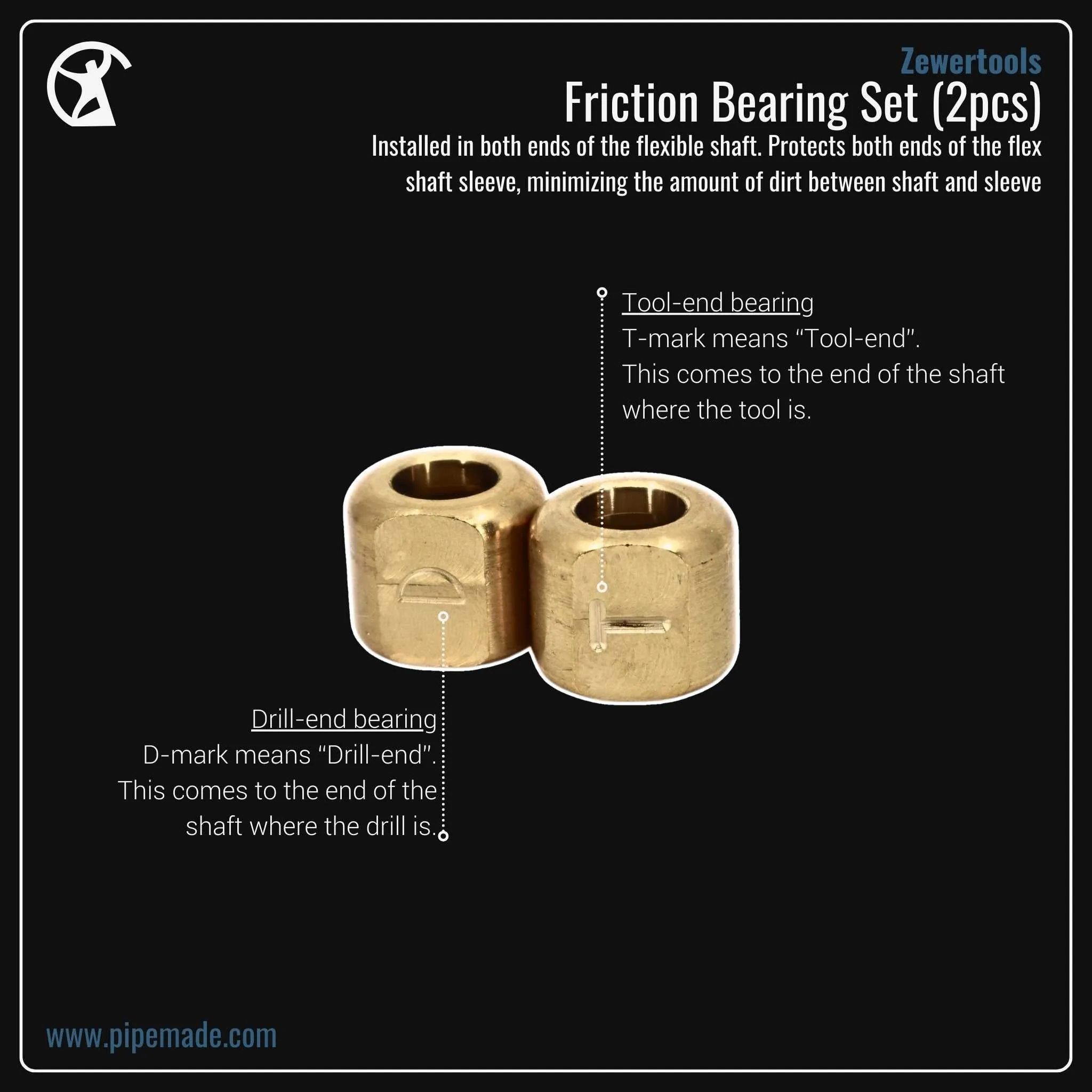

The Friction Bearings Set consists one bearing to both ends of the flexible shaft. Both bearings have a carved letter:

- "D" stands for "Drill" and that end of the flex shaft should be in the drill end

- "T" stands for "Tool" so this end should be in the other end, where the chain knocker, brush, mole or any other tool is located.